Advantages of Haloong servo electric screw press

product features

-

1.precision control, quick response

The pressure can be exactly set in advance, every process can be made repeatedly andprecisely, which ensure the products to be homogenized. Servo motor is direct drive withoutclutch, so it can response quickly.

-

2.Reasonable structure, homogenized products

Due to reasonable design of structure, can" t worry about the overload caused by oversizeor uneven heating, and slip jam (or seizure caused by overload). While for the same material,the different repeated pressures can be used to make it gradually deformed and successivelyforged.

-

3. Quick forming, extend die' s lifetime

The speed of slide block will be very quick when it nears to the bottom dead point, so the timeis very short to forming the material, and the forged parts can be completed before it becomescool. In general, for hot forge, theshorter time of forging, the longer lifetime of die.

-

4.Simple structure, cheaper maintenance

The servo motor is direct drive, and it has simple structure and less components, so itsmaintenance cost is very cheap. For normal operation, there is no need for other brakes, theservo motor itself can make slide block to stop. The mechanical brake is only for the secondprotection when power off, so the lifetime of brake is extremely long.

-

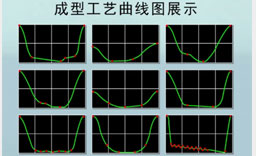

5.Process controlled as planned, wide application range

According to set pressure energy, the servo press can make slide block fall down acceleratedly first, thenslow down the slide block, and press the forged parts with set energy . Also,the press with bigger tons can forgesmall parts, one stroke time is lil change.

-

6.High efficiency, reduce the production cost.

The servo motor runs only at forming process, but the friction motor need run continuously. Compared withfriction press, the servo press can save 55% energy.

-

7.Stamp forming, high energy

The pressurization is the same as that of friction press, the servo press is instant shock pressurized, thepressure energy is very high. For the same forge, the crank press with 1.3- ·1.8 times nominal pressure shouldbe used.

-

8.Lower noise and vibration

Compare with impact hammer, the pressure of servo press produces inside of the frame, there is no excessive vibration to the ground, so the cost of foundation is cheaper. The noise and vibration of servo pressare far less than those of impact hammer.

400 ton servo electric screw press parameters

|

Model |

Nominal Pressure

(KN) |

Permissible Capacity

(KN) |

Kinetic Energy

(KJ) |

Stroke Length

(mm) |

Stroke No.s

(per minute) |

Min Shut Height

(mm) |

Worktable Plate Thickness

(mm) |

Worktable Size FB*LR

(mm) |

Motor

(KW) |

|

HLDS-400F |

4000 |

6400 |

40 |

410 |

27 |

480 |

120 |

820*730 |

67 |

Parameter changes due to technical upgrades will not be notified