SERVO SCREW PRESS Proprietary technology,CE certification

Haloong Servo screw press is used as a servo motor drive, the transmission efficiency is high, the fault rate is low, the motor speed is fast, the split is large, and the digital control energy is released, which can fully forged the hit.

PERFORMANCE:It has the characteristics of strong anti-bias capacity, small mold stress, long life, and high hard work. Experience in energy saving, accurate control of hitting force is better than other pressures. There is no fixed point, no crash can be automatically completed.

APPLICATION:Suitable for die forging, pressing, correction, bending, imprinting. It is an ideal servo electric screw forging press of the train, car, tractor, aviation, hardware tool, medical device, cutlery and other industries.。

Industries with Servo Motor To creat a better future with Servo

-

Aerospace field

For all the moving parts, about 10% cost of a missile is servo control product.

-

Medical field

From the radiology to the operating table, the servo precision motion control provides effective treatment for medical care.

-

Electric car

With the development of electromobile industry, drive motor related skills are promoted. Servo motor becomes the first choice.

-

CNC machine tool

The servo control system is an important part of the CNC machine tool. The accuracy and speed indicators of the CNC machine tool are determined by the servo system.

Servo service forge The beginning is the peak

-

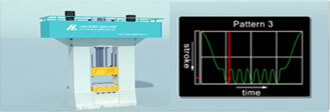

Implement a variety of complex blow craftsmanship

Digital settings ensure consistency of forgings, and do not need to operate experience, make easy blow; flexible chemical curve expansion products, extension of complex products.

-

Energy saving, vibration reduction, noise reduction, environmental protection

Servo motor only turns when the machine is running, so the energy saving effect is more than 55%. Since there is no need for clutch, flywheel and other parts, it reduce the noise, vibration effectively.

-

Implementation automation

It can realize automatic loading and unloading, automatic mold spraying, automatic molding, automatic demoulding, automatic picking, automatic transmission and placement of various processes of unmanned automatic production.

-

Check in Haloong’s Cloud

Haloong intelligent production management system can realize that boss, factory director and workshop director to check their corresponding business. You can check the factory situation by mobile phone, computer anytime and anywhere.

Improve quality and increase efficiency This is the start of forging 4.0

-

-

Improve profitability Servo electric screw press, digital control of the production process, greatly improve the accuracy and quality of products.

Product extension

Product extension

To set strike intensity, strike frequency, strike speed automatically according to different molding process requirements.

Docking automation

Docking automation

The servo electric screw press can be organized into the full automatic production line, completely without the skilled degree of workers during the automatic operation.

Industry trends

Industry trends

The world famous press enterprises all adopt servo drive

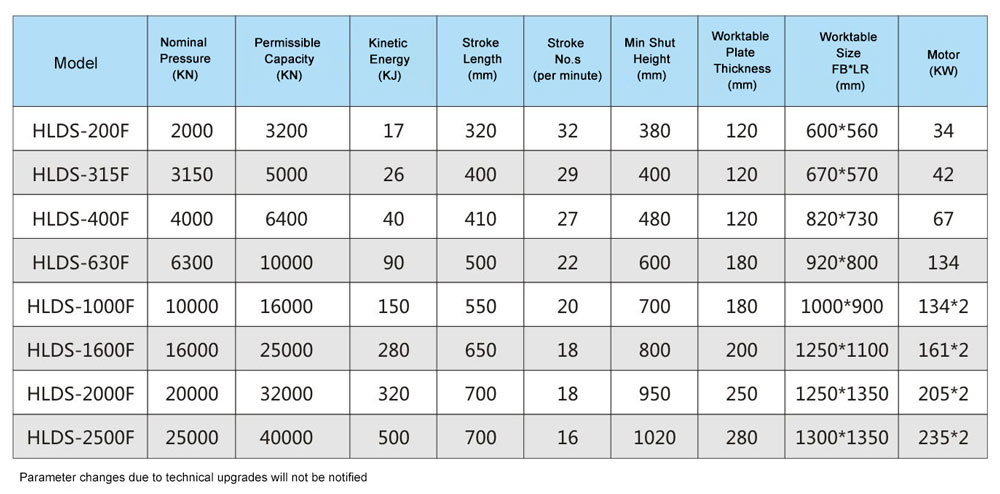

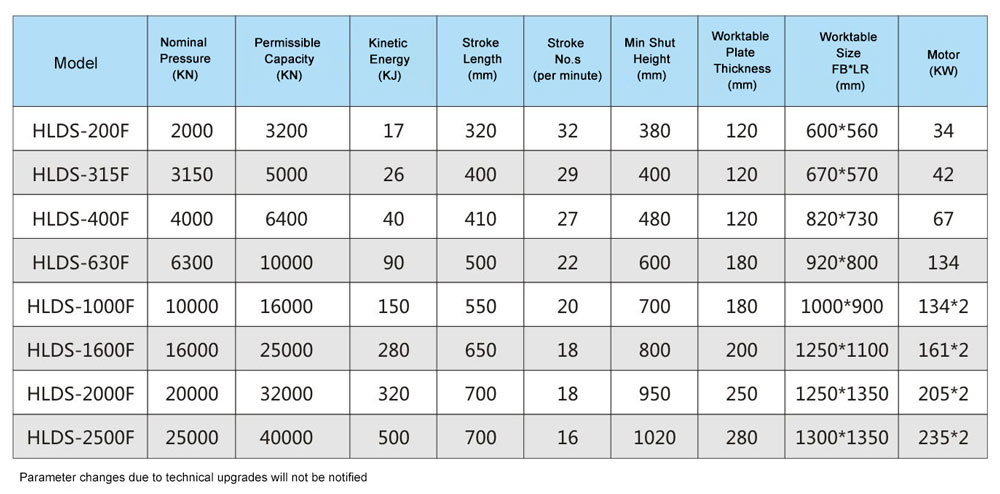

Main technical data of Servo Electric Screw Press

Product extension

Product extension

Docking automation

Docking automation

Industry trends

Industry trends